TONNELLERIE BERTHOMIEU & ERMITAGE

VINIFICATION INTEGRALE® : TURN YOUR BARRELS INTO A RED FERMENTER!

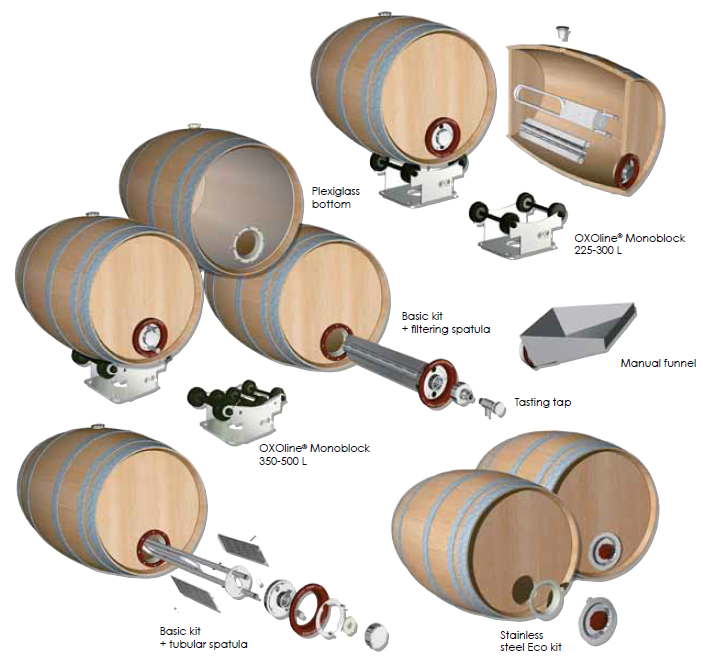

BERTHOMIEU now offers Vinification Integrale® method and accessories, an exclusive process to vinify wines.

SUGGESTED USE

1- Filling the Barrels with harvested grapes

The barrel should be filled to around 85 % of its volume. For example, 340 L of must should be placed in a 400 L barrel. The best results are seen when the harvested grapes are destemmed, but crushing remains optional.

- The barrel can be filled by gravity, directly after a sorting table, optional funnel, manually, or by pump (maximum diameter 100mm).

- Addition of sulfur

- Rotate barrel several times to achieve homogenization of must within barrel.

If a cold maceration is desired before fermentation, dry ice may be added to the must progressively, or our optional thermal exchanger may be employed..

2- The alcoholic fermentation

Once the alcoholic fermentation has started, the temperature should rise naturally to 25-26C for a 225 L barrel and to 28-29C for a 400 L barrel. Nevertheless, it is possible to use our electrical heating kits to reach the desired temperatures and allow better temperature control.

- 6 – 8 rotation cycles per day are recommended (1 cycle : a 360 rotation in one direction, then in the opposite direction, open the bung to release the pressure and then repeat a second time)

- Sparging with Nitrogen is possible, if desired.

- Micro Oxygenation may be employed via “ox box”, if desired.

3- End of the alcoholic fermentation - Post fermentation maceration

- During the post fermentation maceration 1-2 rotation cycles can be performed daily.

- The desired temperature can be maintained using our optional heating kit, or by regulating the temperature of the room.

4- Racking, MLF, ageing

- Racking the wine can be accomplished through the Basic Kit and Draining Paddle, an esquive, or by removal of the Eco Kit for draining directly into the press.

- The must comes out easily with the help of a stainless steel scraper

- After cleaning, the same barrels can be used for malolactic fermentation and wine ageing